What’s the best way to maintain optimal product flow in your pipeline and maximize return on your investment? Tell us your challenges and we’ll help you find the solutions.

- Admenesterial Activites

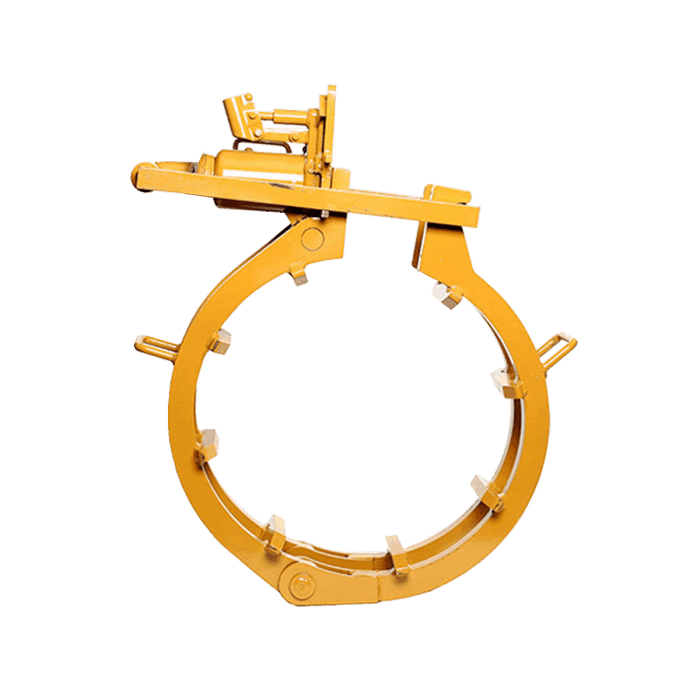

- Equipment

What’s the best way to maintain optimal product flow in your pipeline and maximize return on your investment? Tell us your challenges and we’ll help you find the solutions.

- Services

What’s the best way to maintain optimal product flow in your pipeline and maximize return on your investment? Tell us your challenges and we’ll help you find the solutions.

- Resources

- Company

- contact us